Chassis Prototyp (http://www.jomar-cars.com/)

What you can not read in the books.

One thing quickly became obvious after I looked at some early Granturas – nearly no two TVRs are identical in terms of originality. The reason for this may have been the introduction of frequent design changes at the factory or cars having been built-to-order i.e. one-offs to meet a specific customer’s whims or simply that cars were modified by customers after delivery. A shortage of components in the supply chain for whatever reason could also have resulted in variations.

Existing books about early TVRs contain a lot of information about the company’s history as well as the cars but I’m missing technical details or design nuances which were probably not even documented by the manufacturer. Below are examples of a few points which I consider worthy of mention.

the Chassis tubes

Suspension

Rose joint upright

Magnesium upright

Front suspension Adrian Liepins

BMC A ´series diff in early MKI and prototypes

Inner rear drum-brakes

Inner rear disk-brakes

Steering wheel

Rack and pinion steering

Aluminium brake back-plate of Austin Healey

Lightweight models

Wobbly web wheels

Door handles Lotus Elite

Exhaust outside in the sills

Lightweight bonnet

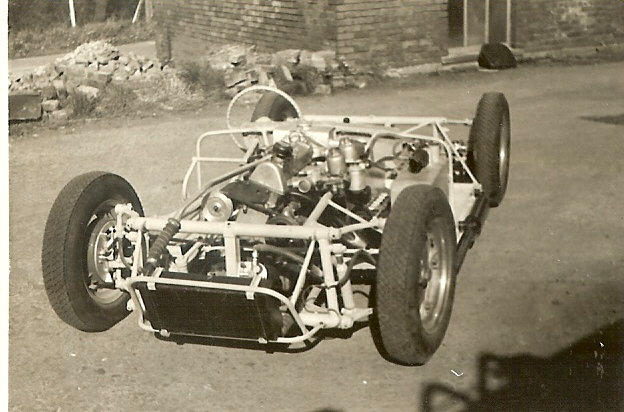

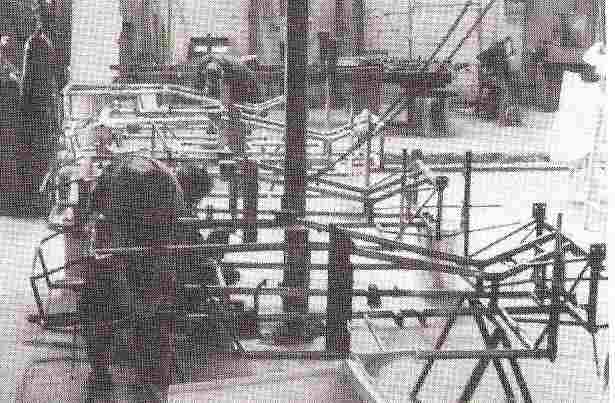

Let’s start with the chassis.

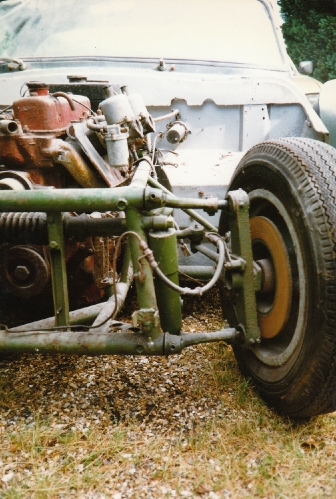

When renovating an early Grantura it is natural to first take a look at the chassis with a view to making it either lighter or more rigid. It soon becomes obvious that the two parallel chassis tubes alongside the gearbox-tunnel run very close together although there is no space constraint. Logically, higher placed tubes would make the backbone more stable and stiffer so today most owners modify the chassis with tubes extending from the rear of the backbone to the front along the tunnel to the two upper tubes of the engine compartment. This makes the chassis more rigid and lends the whole frame more stability.

If you look closely at Peter Filby’s book you will see that early Grantura and Jomar chassis were actually made like this. To date I cannot figure out why the MKI was later changed to the MKIIa chassis.

In my opinion this standard chassis structure isn’t ideal from a strength viewpoint and definitely not rigid enough for racing. I think this is the reason why Grantura race cars are modified to reflect the early design.

However, this chassis feature is not the reason Granturas experience directional stability problems when travelling fast on bumpy roads. This ‘self steering’ effect can be attributed to the upright mountings; more specifically in my opinion, to the rubber bushes that don’t permit any vertical movement of the uprights when tightly bolted and which tend to move laterally when not tightened enough to allow movement of the trailing arms with the uprights. This is valid at least for the rear uprights. Once when driving an MKIIa from England to Germany on the Belgian Motorway I experienced a similar sensation to driving my Sunbeam Tiger at 200 kph; I needed two lanes and had to drive down the dividing line because the car couldn’t hold a straight line at high speed. (Was it not Colin Chapman who discovered directional stability comes from the rear suspension?)

That this suspension weakness must have been known in the early Grantura days became clear to me the day I was offered two ‘rose jointed uprights’. These rear uprights hadn’t been modified in a garage workshop; they were professionally made at least of the same casting quality as the originals and interchangeable with the standard parts. Instead of the bolt which goes through the upright eye into the trailing-arm they have a rose-joint screwed into the trailing-arm and another bolt in the upright going through the eye (rose) of the rose-joint. As one can see the casting is made from a different design mould and the casting quality is very good for that period. For me it proved someone must have had the ‘self steering’ problem and the limited movement when the rubber bushes in the uprights were properly tightened. However, to date I have not found any other examples of this design nor have I found out who developed it and who used it in whatever events. Even a scrutineer and race driver I had the chance to speak to had not heard about this suspension variation.

A logical consequence in my opinion is this version of the rose jointed upright described before. It is the same upright with just the rose joint fitted in a different way. The effect of preventing the self steering as described should be impossible with this construction.

Another very interesting item in the Grantura’s technical history is a rear upright made of magnesium. Basically it used the same design as the standard one but must have had different steering arms compared to subsequent versions.

The ‘standard’ steering levers came from Austin (Healey) as did the brakes but the fitting holes for connecting the lever to the steering arm have a different pattern on the magnesium upright and the smaller arms from the Austin Healey Sprite wouldn’t fit either. To me this would indicate the factory constantly experimented with ideas to improve the cars.

Note the two steering arm fitting holes on the left upright are closer together than those of the right upright.

Another at first rather strange looking but very interesting front upright design is shown in the following picture.

So far it is not known who designed and built it. Another question is whether the roll radius of the upright is small enough and if the steering radius is practical. It doesn’t look bad but I have not had a chance to test it. Nevertheless those who constructed this upright were aware of the problems with the rubber bushes on the mounted uprights.

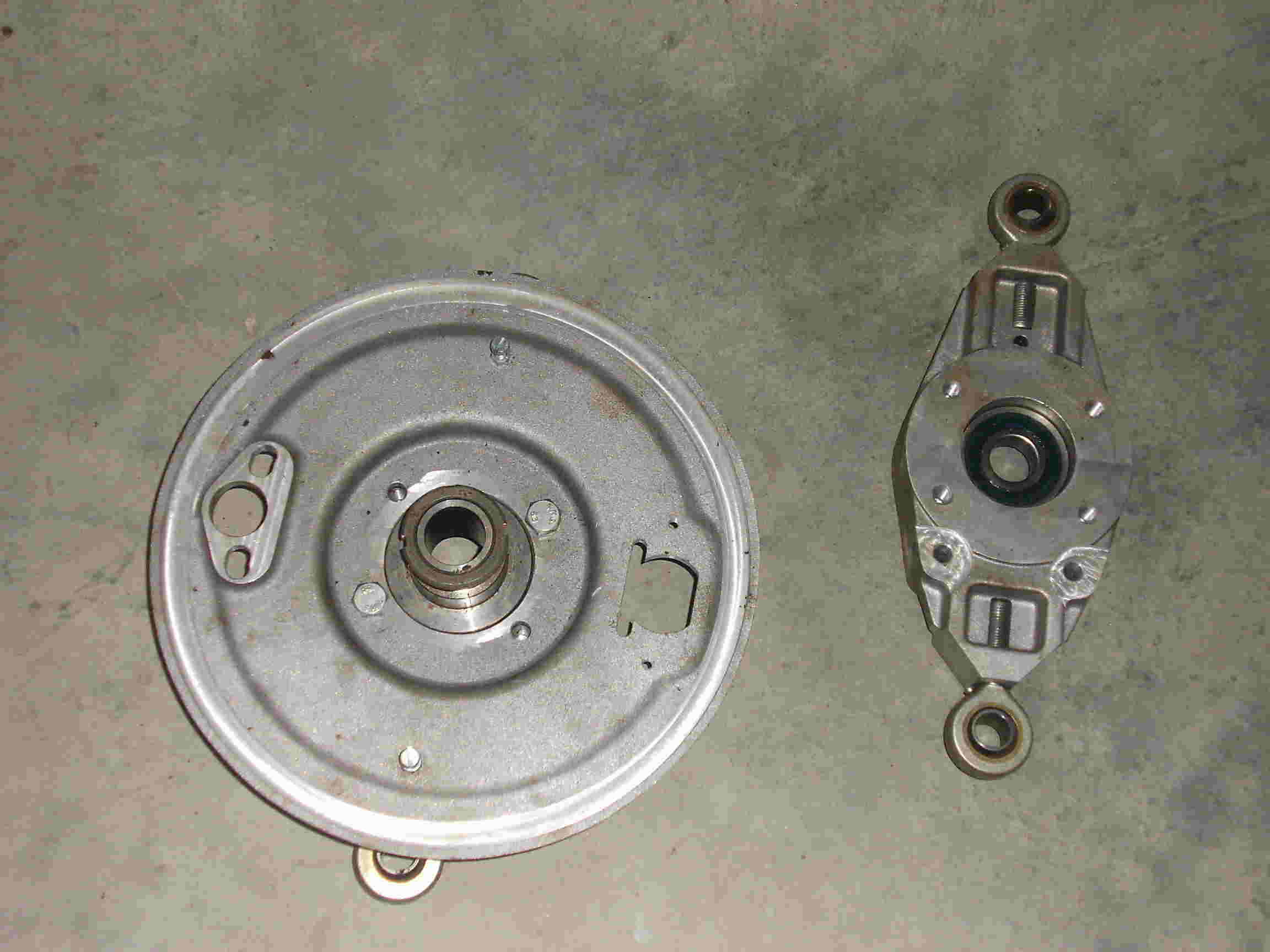

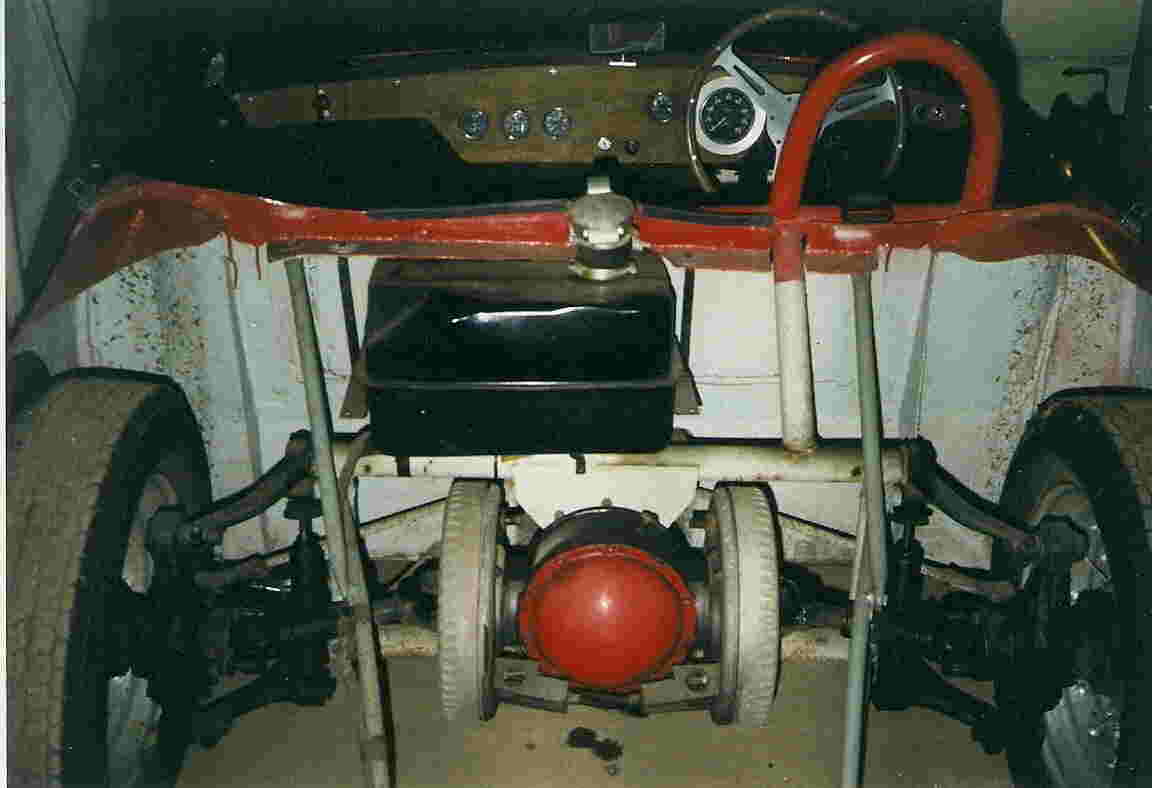

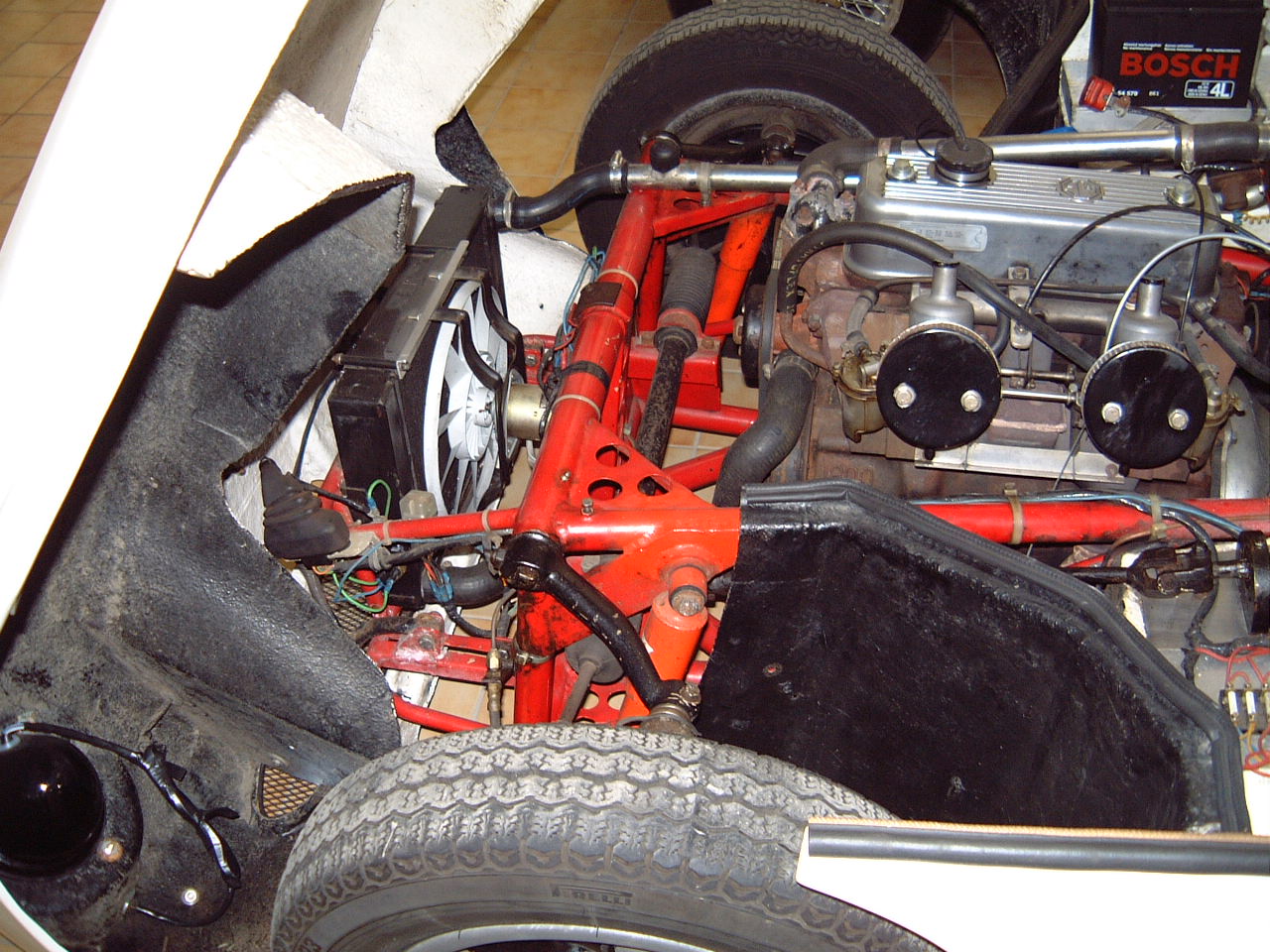

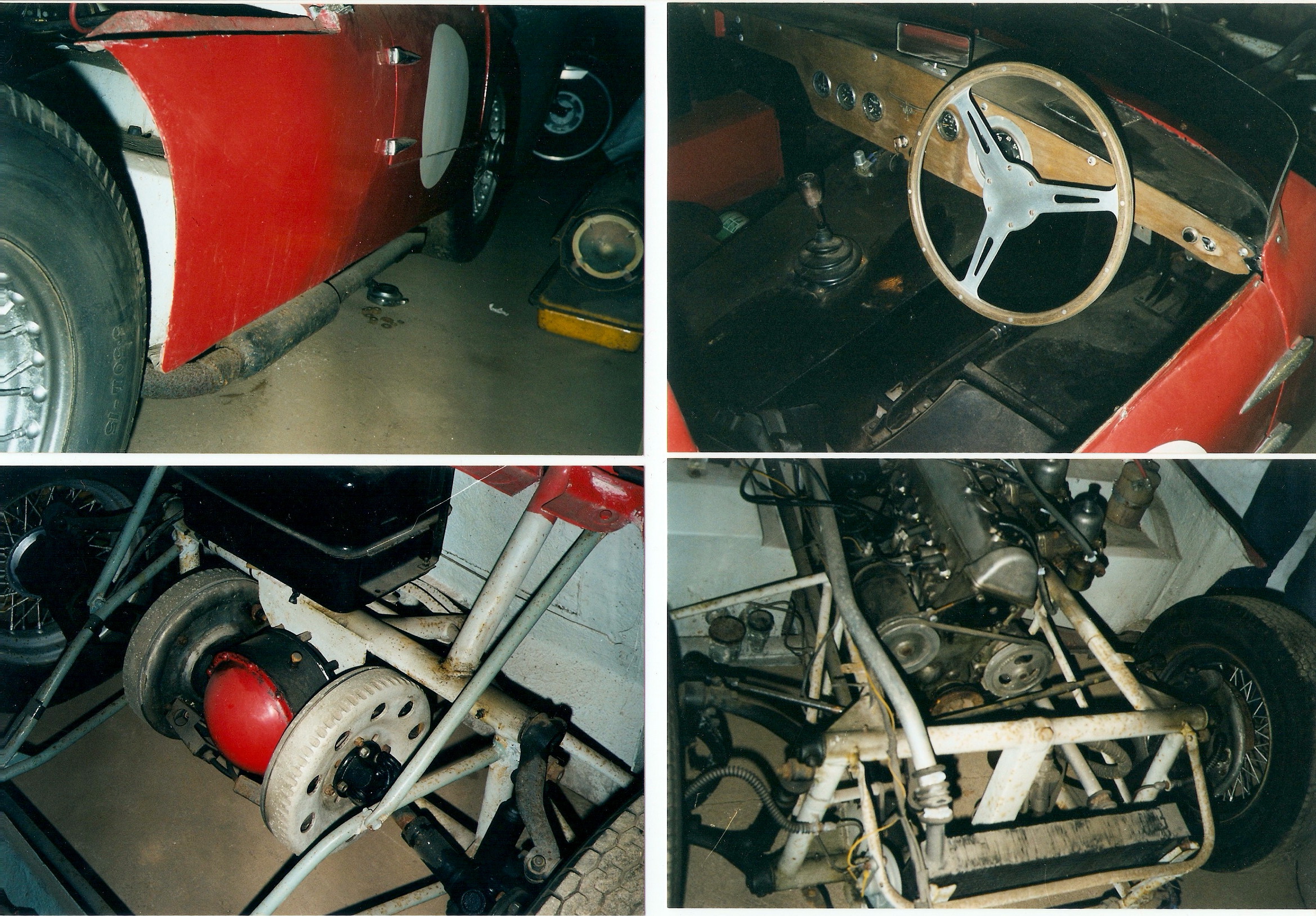

The next technical rarity concerns inboard rear brakes. Prototypes already had inboard drum brakes as can be seen from books and the following pictures which I took of one of the known three prototypes.

There are some later production Granturas which also have this technical rarity. I don’t know if this construction was developed by a private enthusiast or racing driver or was an option offered by the works and whether or not it was homologated. RAC documents do not mention inboard brakes but these inboard disk brakes look quite well made so they may well have been developed by the TVR manufacturer.

I never managed to take a closer look at this diff myself so if anybody can send me more detailed pictures I’d appreciate it very much.

This above diff with drum brakes seam to have been made by an experienced home constructor. It is hard so say whether it was used for racing or just for fun the drums however do have the same design as drums which are used today for upgrading TR s and can also be found on Lotus 23 s etc.

It should be mentioned, that the diff of the prototypes and early Grantura MKI and the late

MKI-MKIIa are different. The early Granturas and prototypes used the BMC A series differential housing whereas later cars used the B series diff from BMC both with TVRs own

casing design – see pictures of BMC A series diff below.

I want to ad the following correction to the above text as it is obviously wrong.

Ian Rainford from Colorado , owner of 7C107 for 25 years has sent me the following statement:

"I believe that the differential used on the early Jomar/ TVR was from an Austin A90. The A90[A2.5 liter car]

was what the veryearly Austin-Healey 100-4 was based on. The only reason that I can think of that TVR used this diff was that the front oil sealretainer was attached by 4 bolts making it convenient for TVR to attach their front diff mount. When Austin became part of BMCthe diff was redesigned and was known as the "C Series" No parts were interchangeable with the A90 diff. As you say the later cars used the MGA" B Series" diff."

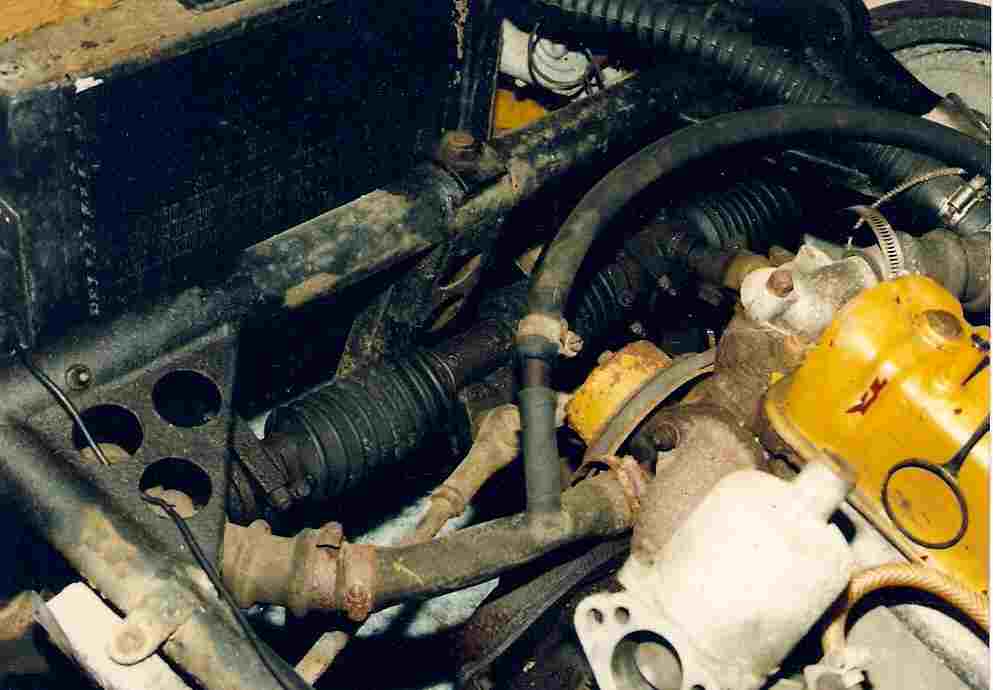

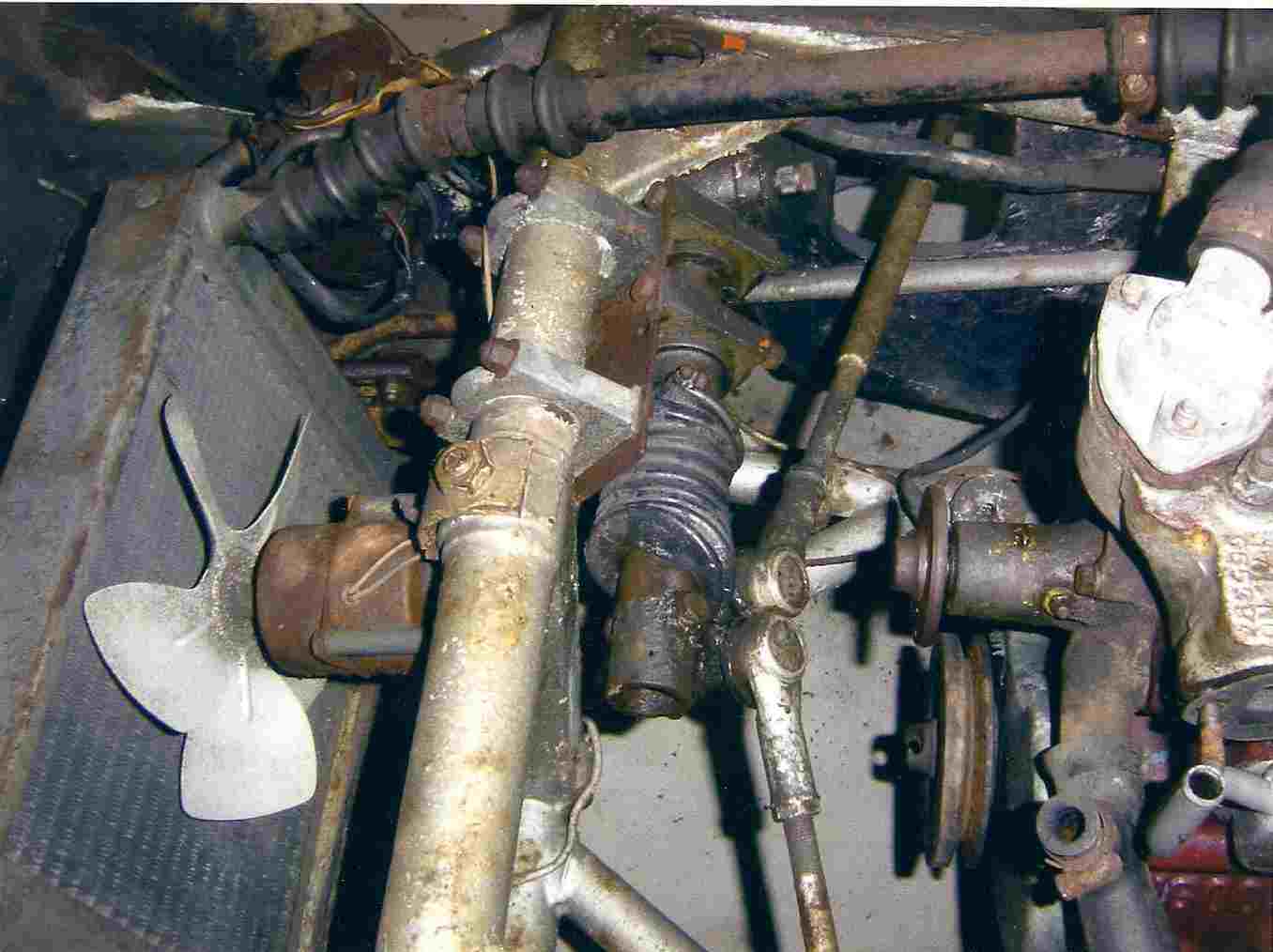

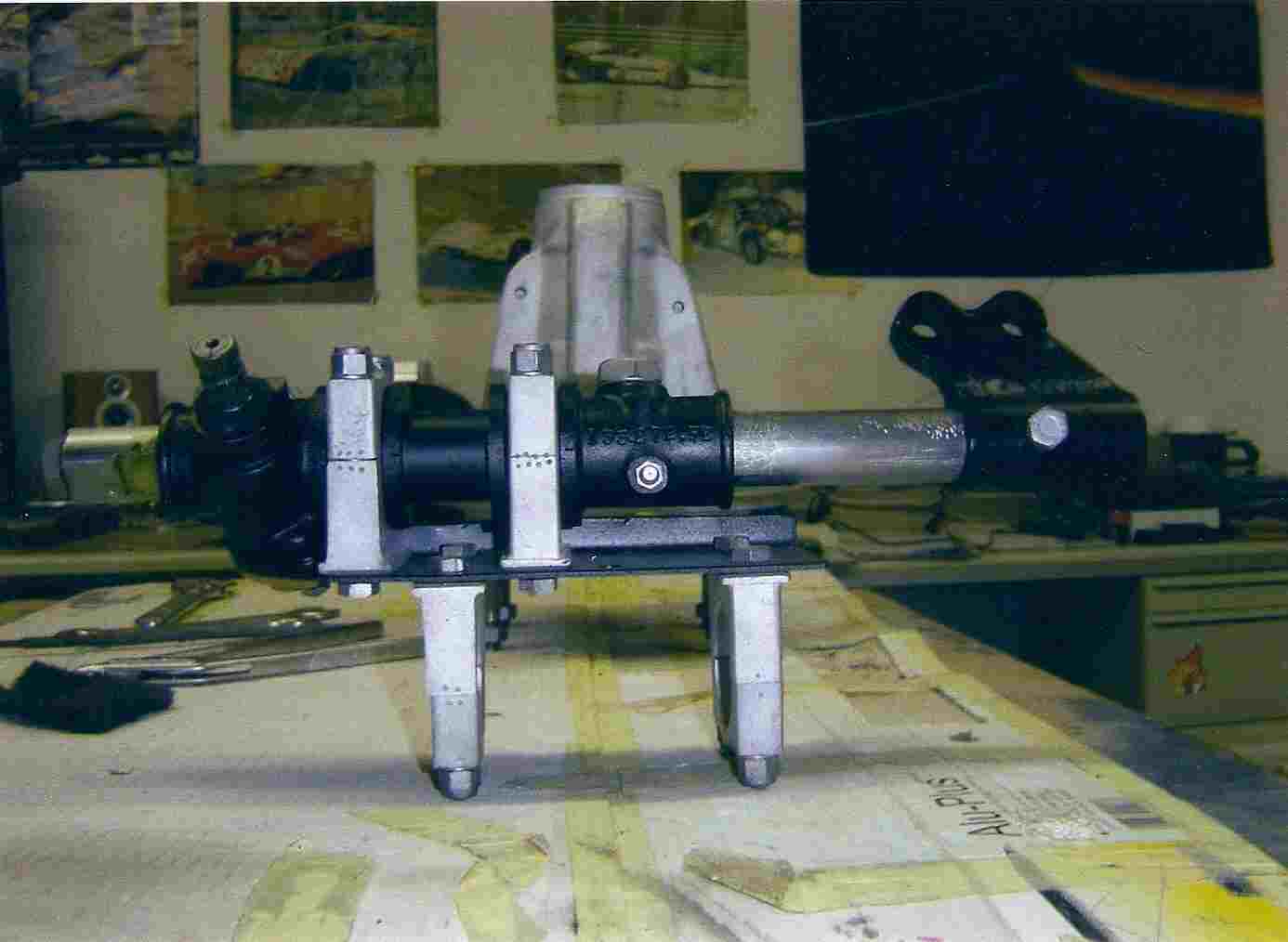

Rack and pinion steering is also a frequently discussed point in conjunction with Granturas

originality. In many articles and most books it is mentioned that this kind of steering was an option mainly for Coventry Climax powered cars, but it was not homologated by the FIA. I have seen a few photos of Granturas with rack and pinion steering and I have seen Adrian Liepins’s car with the steering shown in the photos, but all the steering racks look a bit different. I mean they had similar systems, but all of them were modified in one of two different ways.

It looks like the steering gear from a Morris 1000 only modified so that the steering rods are mounted in the middle of the car. They are of equal length instead of the offset and unequal length rods found on the standard Burman Hinton steering.

One might say why not just take a normal TR or Morris 1000 or any other steering rack and connect the steering arms of the uprights via the normal rack end, but I think in this case one would have to mount the steering gear to a different point on the chassis or you would have to turn the steering levers around at the upright to attach the steering rods in front of the upright.

However, it is interesting that at least the prototype I have seen does have the standard worm and peg steering. And one of the other prototypes in the USA also uses the Ford steering which is LHD steering gear fitted upside down on the right side for RHD cars and a RHD steering gear fitted upside down on the left side for the LHD cars.

Note this Rack & Pinion steering is similar to Adrian Liepins’ car above. This car was exported to the USA. The holes in the chassis gussets and in the middle between the cross torsion tubes would indicate a lightweight version.

The following pictures shows a modified Morris 1000 steering rack, and it might well be possible, that this construction is also like the above one a factory version.

As one can see, it’s a left hand drive car and therefore I would say probably a later conversion because the Burman steering gear for the LHD car should be a RHD steering gear mounted upside down. Since these are not so easy to find they chose the logical way and used rack and pinion gear. The steering rods however look very professionally made.

The rack and pinion steering illustrated above is probably not a works version; it looks like it has been privately modified later in life. This car may be located in Germany.

Standard Burman steering gear as used on Ford Anglia

Steering wheel similar to Triumph TR3 but with TVR indicator switch

Austin Healey brakes!

It is fairly well known that the front uprights come from BMC (Austin Healey) and the brakes too. Early front and rear drum brakes however have aluminium back-plates which I cannot find in any Austin spare parts catalogue. Please contact me if you know otherwise. The standard back plates are of steel and so far nobody seems to know where the Grantura’s aluminium brake back plates were originally used. Even specialists from the UK Austin Healey Club affirm that there is no aluminium brake back plate for Austin Healeys. Nevertheless I once bought a set of drum brake back plates made of aluminium and the seller told me that they came off an Austin Healey 100/4. I still do not know the truth but I decided to make new rear back plates anyway as the old aluminium ones were more or less disintegrating. To be honest I rather believe that the plates are Healey as TVR also offered Healey Alfin Drums as an option.

Many of the aluminium brake backplates are in a very sore condition and should be replaced for safety reasons.

Healey Alfin drums as an option

Up till now I have only mentioned mechanical/technical features but there are also some oddities in the bodywork and accessories areas. Examples are the steering wheel, door handles, air outlets in the driver’s compartment, lightweight bonnet, side exhaust pipe and wobbly web wheels. There might be more variants to the normal ‘production’ cars but I do not want to discuss items like air scoops on the bonnet as these may be individual modifications made by the owner or ordered by them.

Lightweight variants are mentioned quite often but neither the authors of the books nor most

enthusiasts and collectors have ever seen one. The two pictures below show the main visual

differences between the much thinner GRP of a lightweight bonnet and the standard one. As one can see are the indicator lights moved to the front of the bonnet and are embedded similar to the headlights. Additionally the fibreglass structure is much thinner than the standard bonnet as is the bodywork.

There is a rectangular air outlet at the upper end towards the windscreen .

Apparently this lightweight Grantura car has a racing history which hasn’t been documented. Its registration number is 760WAR. If anybody can put on some light on the unknown history, it would be very much appreciated.

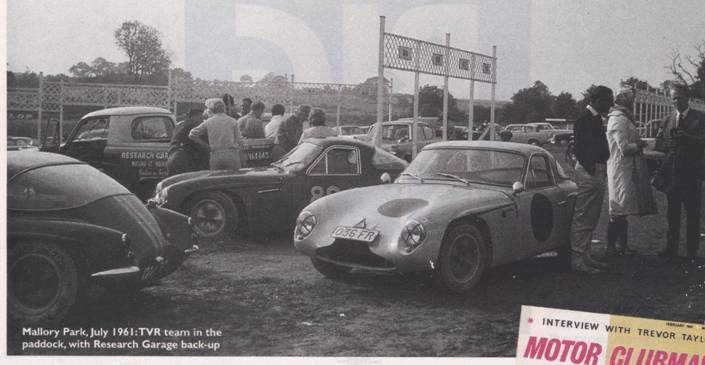

The above car shows another Grantura option as is magnesium Wobbly web wheels as were also used on early Lotus 7s. They are 15” in diameter and 4,5 “ wide. So far the manufacturer is unknown. But as you can see on the next foto which shows a scene in the paddock of Malory park they were very popular during their days.

It is interesting to see that the PCD of this wheels is different to the PCD of the standard Grantura rear and front suspension with the wire wheel hubs. It is not the Austin Healey PCD from the 100/4 but the MGA or TR range PCD of 4 ½ inch instead of 4 ¼ of the Healey.

Air outlet for interior ventilation on a lightweight car.

Lotus Elite door handle on same light weight

Lotus Elite door handle on a race car

Note the the Perspex side screen. I have heared in the past that some FIA screwteneers would not have accepted these screens as they are not original works modifications as they say. However they were allowed those days.

Grantura MKI with Coventry Climax engine. Note the cutout in the door sill for the outside

exhaust pipe, as can also be seen on the prototypes.

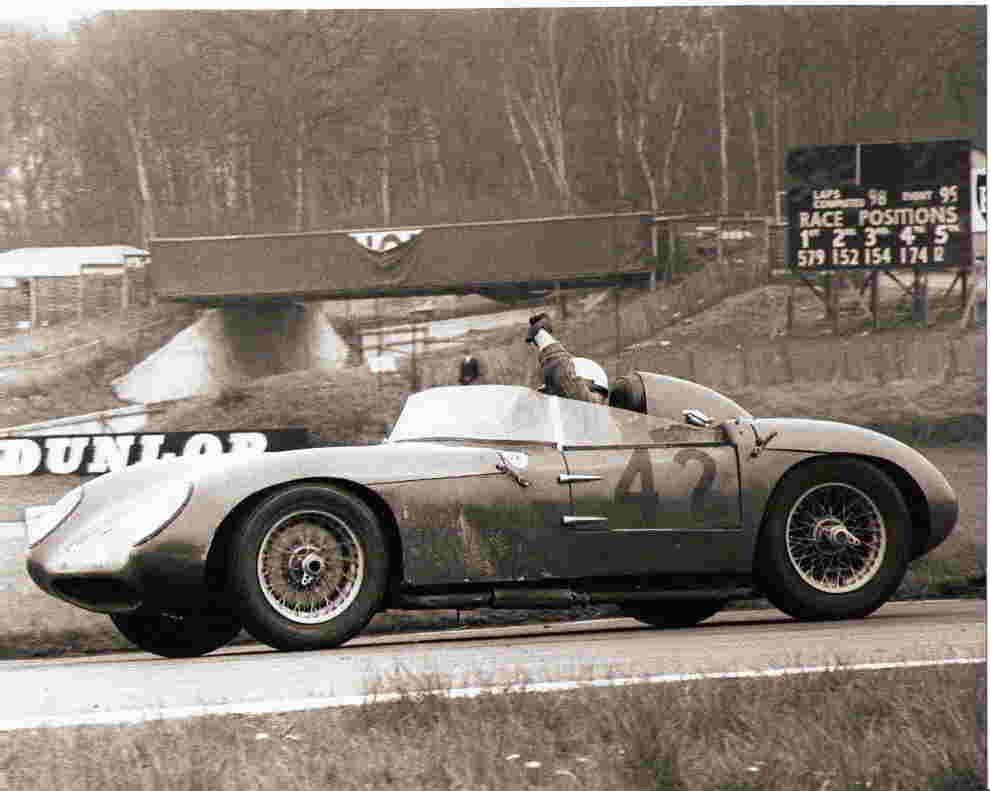

One of three „ptptotypes in action on a race track. Might be Brands Hatch

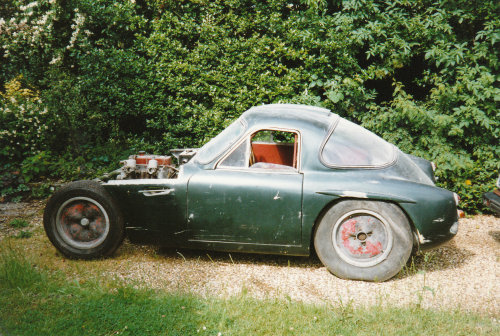

The same car many years later as found in a collapsed barn .

and after an older restoration in UK.

One of the two other prototypes, this car is in the US.

Miroplas Mistral body . Its bonnet is the base for the front and rear of the three Grantura prototypes and which is further developed to the Jomar and Grantura body.

To be continued